As a continuation of the first part and to keep moving forward with the introduction of industrial racking systems, it is always important to be clear about some of the most important terms and definitions related to storage equipment and racking.

Terms related to storage equipment and racking

1. Person Responsible for the Storage Equipment Safety or PRSES: is the person appointment by the warehouse management with responsability for maintaining the safe operation of the warehouse storage system. The PRSES has to be informed about the identity of the suppliers, and has to be aware of the nature of operations.

2. Competent person: person who by means of a combination of training, experience and education has the knowledge to carry out the task and safety requirements effectively.

3. Specifier: person or company that provides the supplier with a specification based on the user’s requirements. The specifier can be a consultant or other specialist, the end user or the equipment supplier acting as the specifier.

4. Supplier: company that supplies the storage equipment. The Company can be the original manufacturer or an intermediate company acting as distributor.

5. Lift truck operator: person trained and responsable for the safe use of an individual fork lift truck or a range of such equipment. This would normally be rider-controlled equipment but could also include pedestrian-controlled powered equipment together with hand-operated pallet trucks.

6. User: company or person who manages and operates the installation on a daily basis and is responsible for the continuing safety of the installation. Fort he rest of terms and definitions please see following norms: EN 15512, 15620, 15629, 15635 and 15878.

Industrial racking systems, classification of warehouses

It is useful to know what types of warehouses that exist. There are two main groups:

- Manualy operated warehouses: manualy operated warehouses are those that require the direct human intervention. Are warehouses operated by means of lift trucks or similar handling equipment.

- Automated warehouses: are warehouses operated in an automated manner, controlled by software and in general are connected witht the ERP system of the company. Those kind of installations used to be big in size operated with stacker cranes.

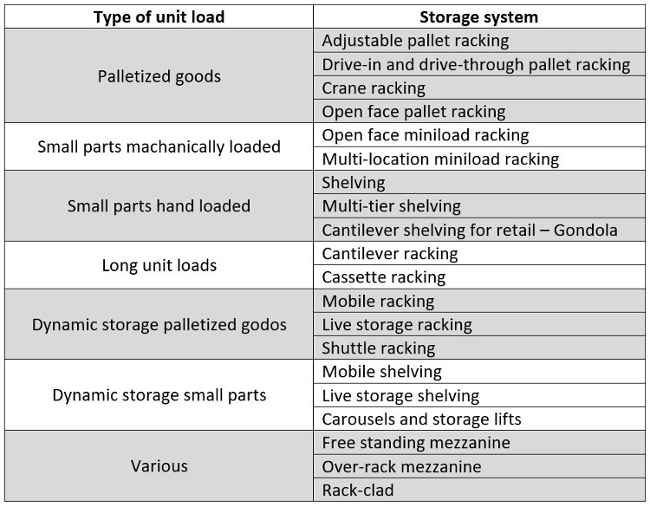

Classification of storage equipment

According to the norm EN 15878 “Steel static storage systems. Terms and definitions”, the storage systems can be classified as shown in the table below. A storage systems is a steel racking or shelving structure designed to store unit loads in a safe and organized way.

Palletized goods. Conventional pallet racking, Adjustable Pallet Racking (APR).

Conventional pallet racking for palletized goods is the most extended type of industrial storage systems. Pallet racking allows the access to every loading unit any time.

The system is built up of upright frames connected bt horizotal beams to provide unit load storage levels which can be adjusted vertically.

Palletized goods. Drive-in (compact storage).

System of racking that provides blocks of storage where pallets are stored two or more deep and where access is gained by driving a forklift truck into a lane with pallets supported along their sides on beam rails supported from the uprights. Drive-in storage systems follow the LIFO (Last-in-first-out; last pallet stored is the first to be retrieved) principle.

Palletized goods. Racking served by stacker cranes.

What is particular about this system is that it is operated by stacker cranes, rail guided on top and bottom.

Palletized goods. Open face.

One loading unit is storage in each level and bay. The storage levels consist of beam rails or arms.

Small parts hand loaded. Shelving.

Comprehend those storage systems manually operated by hand, without the use of any handling equipment.

Small parts. Multi-tier shelving.

Storage system operated by hand, with two or more personnel accesible floor levels, that allow the access to the goods in all the height.

Long unit loads. Cantilever racking loaded/unloaded by material handling equipment.

System of columns with horizontal cantilever arms suitable for the storage of lengthy goods (timber boards, tubes, beams,…).

Long unit loads. Cantilever racking loaded/unloaded by hand.

Loading and loading executed by hand.

Dynamic storage. Mobile racking.

System where the racking is mounted on mobile bases running on rails, which can be power operated or mechanically assisted. Working aisles are reduced to only one aisle achieving an import saving in space.

Dynamic storage. Pallet live storage.

Storage by accumulation in depth. Racking equiped with rollers, wheels or trolleys to allow the movement by gravity of the unit loads. FIFO (first-in-first-out) principle, where the first load unit stored is the first unit tobe unload at the other end of the racking.

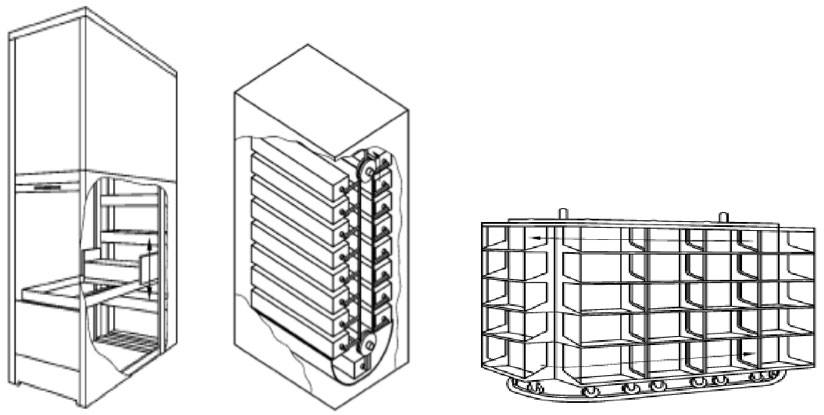

Dynamic storage. Carousels and storage lifts.

Horizontal and/or vertical circulating storage equipment with load carriers (freely suspended carriers, suspended rods, etc.) which can be provided with one or more access openings.

Dynamic storage. Shuttle racking system.

Is a semi-automated storage system that accumulates the loading units stored on rails in depth. The system can be designed following either FIFO (loads and unloads from the same side) or LIFO (loads from one side and unloads from the other side). Together with the lisft truck also a shuttle car is required to operate the system.

Storage on mezzanine. Free standing mezzanine floor.

Is a removable storage system that allows the creation open space areas in the height, able to support live loads or actions originated by other installations put on them.

Storage on mezzanine. Over-rack mezzanine floor.

Mezzanine area supported by racking or shelving system suitable for storage, ciruclation, support for other equipment, offices, etc.

Rack-clad storage system.

Is a storage system designed to support the loading units, as well as side and roof cladding, wind and snow loads, and seismic actions specific to the location of the warehouse. Is a self-supporting warehouse where the racking itself is both storage equipment and structural construction of the building.

At Noega Systems we are specialized in the design, manufacture, assembly and inspection of all types of metal shelving, industrial and storage systems. If your company needs advice in this area, do not hesitate to contact us.