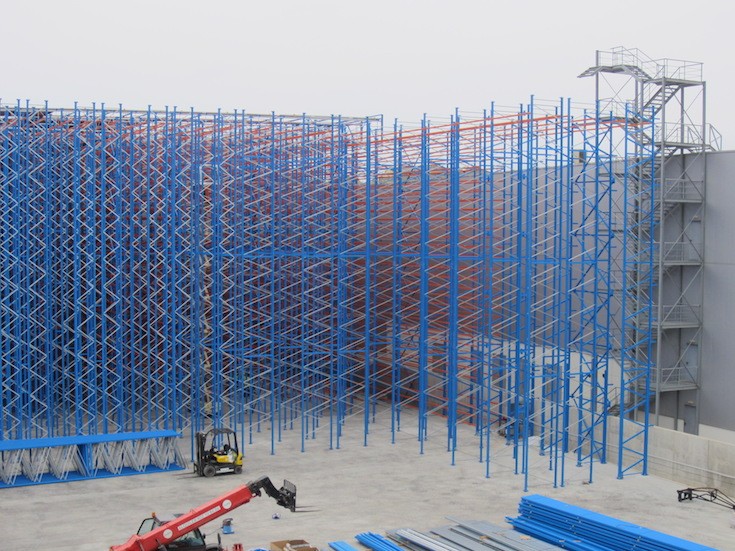

Self-supporting industrial shelving are advanced technological storage systems that allow for the storage of palletized loads at elevated heights (over 40 meters). They serve the dual function of being both storage equipment and the structure of the building to which the exterior enclosures are attached.

Noega Systems has demonstrated its capacity for innovation with the creation of a state-of-the-art self-supporting warehouse. This article explores this success story in detail, highlighting its features, advantages, and the positive impact on our client’s operations.

One of the main characteristics of self-supporting warehouses is that the shelving constitutes the load-bearing structure of the warehouse building.

These systems are designed to support the load units as well as the enclosures, and to withstand the forces of wind, snow, or seismic activity corresponding to the location of the installation.

Project Features

Custom Design

The Noega Systems project is characterized by a fully customized design, tailored to the specific needs of the client. This approach ensures that every inch of available space is used optimally, offering a bespoke solution that maximizes storage capacity.

Cutting-Edge Technology

The implementation of cutting-edge technology is another key aspect of this self-supporting warehouse. From automated inventory management systems to advanced security solutions, each component is designed to enhance operational efficiency and ensure the safety of workers and stored goods.

Advantages of the Self-Supporting Warehouse

| Advantage | Description |

|---|---|

| Maximization of Space | By eliminating the need for additional support structures, more space is freed up for the storage of goods. This is especially beneficial in areas where space is limited or expensive. |

| Cost Reduction | The integration of the shelving into the building’s structure allows for a significant reduction in construction costs. Additionally, the operational efficiency provided by this type of warehouse contributes to a decrease in long-term operational costs. |

| Flexibility and Scalability | Self-supporting warehouses offer great flexibility and scalability. They can be designed to accommodate different types of products and storage volumes, and can be easily expanded to meet the future needs of the business. |

Impact on Client Operations

Increase in Efficiency

The implementation of the self-supporting warehouse has resulted in a significant increase in operational efficiency for our client. The optimized arrangement of shelving and the use of advanced technology have enabled faster and more accurate inventory management.

Improvement in Safety

Safety is a priority in any industrial environment. The robust design of the self-supporting warehouse, along with advanced security systems, has reduced the risk of accidents and improved the protection of stored goods.

Sustainability

In addition to the operational and economic benefits, self-supporting warehouses also contribute to sustainability. The reduction in the use of construction materials and the energy efficiency of these structures help to minimize the environmental impact of storage operations.

Certificate of Compliance

NOEGA Systems certifies all its self-supporting structures with the CE marking certificate in accordance with the standard EN 1090-1:2009 /A1 2011: “Execution of steel and aluminum structures. Requirements for the assessment of conformity of structural components.”

In conclusion, self-supporting warehouses have the great advantage of reducing costs compared to other traditional storage system alternatives, such as building an industrial warehouse and installing industrial metal shelving inside.

These automatic storage systems become profitable when dealing with high-rise projects and a significant number of load units intended for storage.

For their design, the following considerations must be taken into account:

– The load of the units to be stored.

– The forces generated by the automatic handling equipment.

– The external effects impacting the self-supporting warehouse: seismic movements that may occur depending on the geographic location of the warehouse, and wind or snow loads.

– Additionally, the storage structure for the attachment of the side enclosures and roof must include the necessary elements. The assembly execution can take several months depending on the size of the project.

At Noega Systems, we specialize in the design, manufacture, installation, and inspection of metal and industrial shelving, as well as all types of storage systems. If your company needs advice in this area, do not hesitate to contact us.

dear Sir

could you please provide me with a copy of your standard structural calculation for a typical rack clad warehouse so that i can convince my client to accept your product

Hello Mr. Guiragossian,

Please use our contact form to ensure that your query reaches the right person.

Kind regards,