When we talk about storage we refer to a set of processes aimed to store and preserve our stock in an optimize condition, ready to use, that span from the moment the goods are produced to the moment those goods are requested by our customers. Industrial racking provides the necessary equipment to receive, store and ship raw materials, in-process product and finished goods. Needless to say, that depending on the type of the material to be stored, the racking specification as well as the handling technology may vary.

As a preliminary step to the design of the storage system and the industrial steel racking, it is necessary to consider the specification of the materials to be stored, like dimensions, weight, durability or economic aspects.

The investment in storage equipment has a clear objective: the reduction of storage costs.

Some general concepts about industrial storage racking

- Storage equipment and industrial steel racking are working equipment with a key role in the internal logistic processes of our companies, allowing a more efficient and better use of the available space in the warehouses.

- It enables the storage of our stock in an organized manner, increasing productivity.

- A main aspect without any doubt, is the improvement of safety levels for workers and goods in the warehouse due to the use of storage systems.

- Generally, industrial racking is a static equipment, likened to a general Steel structure, but in constant interaction with mobile handling equipment like lift trucks.

- It must be taken into account that industrial racking and storage Systems may deteriorate with its use and have to be periodically inspected, at least once a year by an external and independent racking inspection expert. Damaged structural components of the racking increase the risks and reduce safety.

- Racking and storage solutions are technically advanced equipment:

- Special structures of open, perforated and thin wall thicknesses.

- Require the use sophisticated calculation software (FEA, Ansys, 3D analysis) and laboratory testing.

- Major technical evolution over time: changes in standards and calculation and design methodology.

- Racking and storage solutions are optimized equipment:

- Enables the storage of a high loads with a relative low weight of racking material.

- Accidental impacts are foreseen and considered in the design and the standards.

- Damaged structural racking components can transform them in very unsafe and risky equipment.

That high optimization level makes our racking structures more sensitive to strikes and damages.

Elements interfering in the operations of a warehouse

Important aspects to be considered in a warehouse and that affect the racking equipment, are all surrounding elements interfering on the operations and the safety. On one side the lift trucks used have to be adequate to the warehouse operations and the installed racking system. On the other side, an adequate lighting of at least 50 lux (100 lux where reading is required), avoid shadows (lighting centered in the aisle) and emergency lighting.

Another aspect not less important is maintaining the warehouse in good conditions of cleanliness and order. Transit areas, emergency exists and circulation aisles must be free of obstacles. It is important to count on a regular cleaning plan, as well as a cleaning action in case of accident.

The warehouse floor has to be free of bumps, crackings and uneveness, to avoid irregular driving of lift trucks, and permit an appropiate erection and leveling of the racking.

Aisle widths have to fit the existing warehouse operations, as well as the nature and the dimensions of stored goods, and the type of material handling equipment used (lift truck specification have to be considered in the design). Inadequate, too narrow aisles can be the origin of accidental lift truck collisions with the racking. Special attention has to be paid to aisle crossings where lift trucks can collide.

Warehouse signs have to clearly delimitate circulation areas from storage areas, and loading docks for lift trucks should be indicated. A weight check for a quick and easy monitoring of loading units is required to decide whether the loading unit can be stored in the racking or not. It is also important to very that the loading units are stable, and attention has to be paid to clearencess and dimensions.

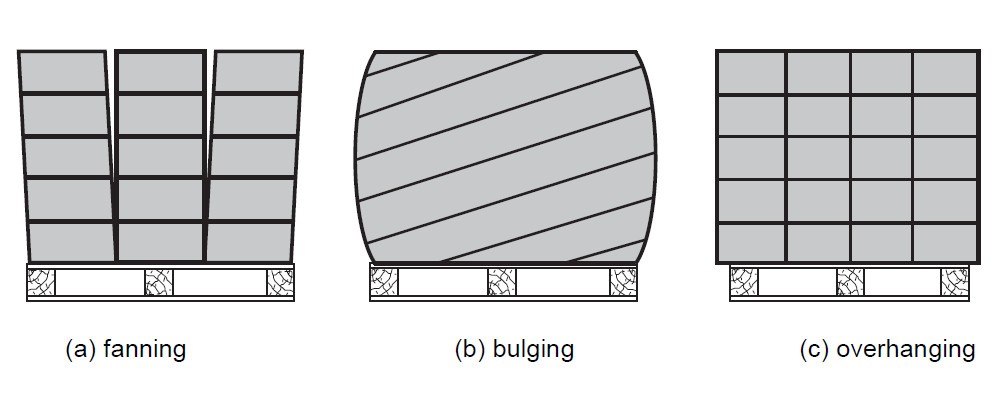

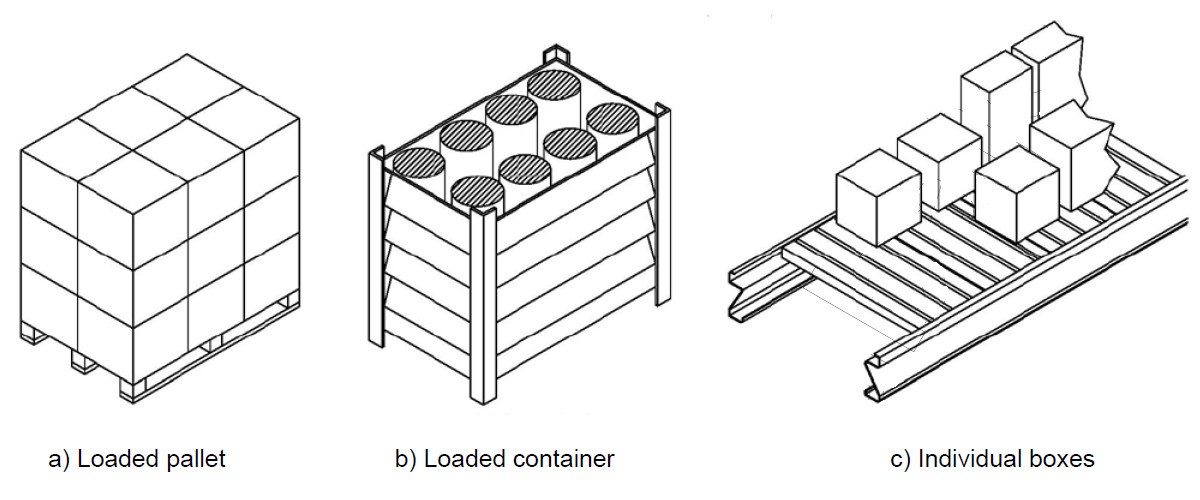

Characteristics of palletized unit loads

The loading unit is the addition of good stored and the load carrying accessory (LOADING UNIT = GOOD + LOAD CARRYING ACCESORY). There are 3 types of load carrying accessories: pallet, container and boxes.

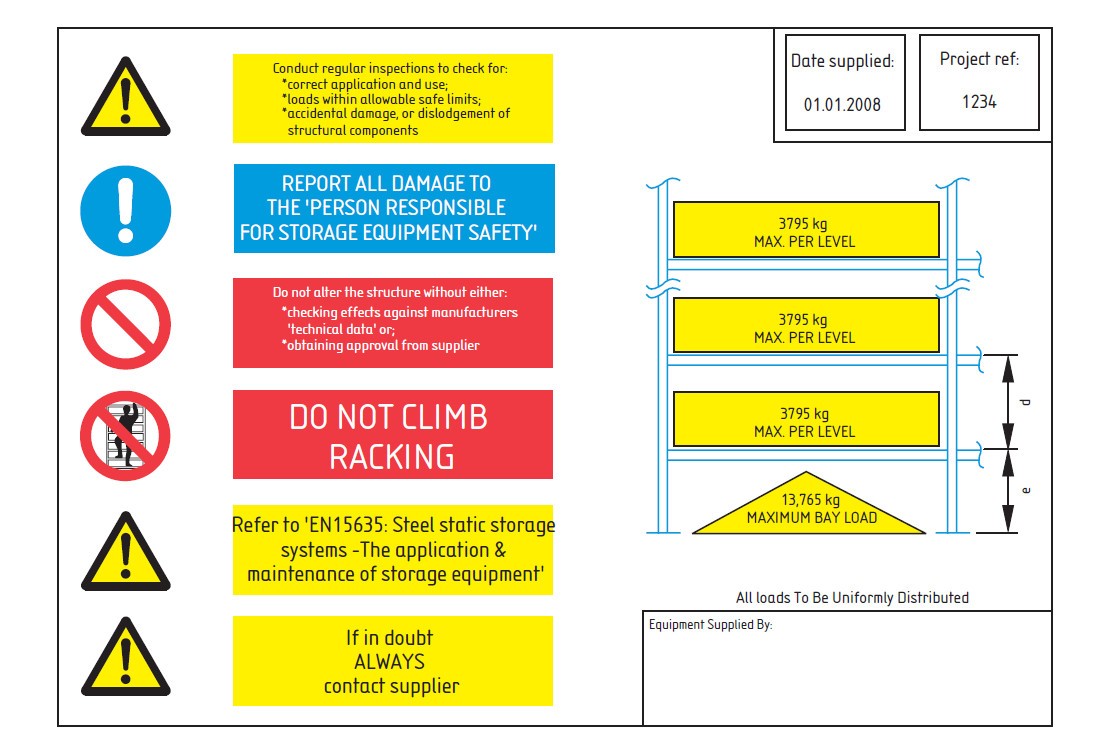

In a warehouse, it is mandatory to place load warning notice with the specification of the installation (loading capacity, type of components, dimensions, etc.). Format according to the norm EN 15635.

Example of load warning notice according to EN 15635

With our next blog post we will continue talking about all related with the storage process, from the type of existing systems, classification of warehouses, and will deepen in the general characteristics of industrial racking currently demanded.

At Noega Systems we are specialized in the design, manufacture, assembly and inspection of all types of metal shelving, industrial and storage systems. If your company needs advice in this area (industrial steel racking), do not hesitate to contact us.