Industrial racking plays a key role in our warehouses and are an indispensable equipment for proper operations in our companies. For a correct and safe functioning, we summarize in this post the preventive actions and the safety elements to use with industrial racking and storage systems.

Conventional storage systems for palletized goods (pallet racking or APR) is work equipment that uncorrectly used can produce damages on the own racking, on handling equipment, on stored materials and goods, and injuries to workers and persons in general. For that reason, prior to starting using this equipment, it is higly recommended that the user pays special attention to both prevention actions and safety elements aimed to reduce risks.

Prevention actions with industrial racking

Among others, the most relevant and inmediate prevention actions to take, are the following:

- Appointment of Person Responsible of Storage Eequipment Safety (PRSES).

- Read and apply the instructions specified with the supplier user’s manual.

- Observe the fundamental information of usage contained in the loading labels. The loading labels must be kept updated with the reality of the installation and placed in a spot visible for all the personnel.

- Carry out a maintainance plan and anual racking inspections performed by an EXPERT as specified with the norm EN 15635.

- Do not make any changes on the rackig without prior permission of the racking supplier and responsable for the design.

Safety elements for industrial racking

Daily warehouse operations bring with it a potentially high risk of accidents caused by crashes, pushes, etc on the racking mainly produced by the material handling equipment while manipulating (loading/unloading) the loading units. Those impacts are more frequent on the bottom of uprights and other frame components.

For all above indicated reasons and in order to reduce safety risk and health issues on workers, there is an array of safety elements to user’s disposal that contribute to reduce risks.

Racking protections

Upright protections. According to the norm EN 15512 it os MANDATORY to protect all the uprights in the corners, in the instersection of working aísles.

Additionaly, with levels of traffic and unit rotation, Además, cuando el tráfico y la rotación de la mercancía a almacenar sean elevados, it is also recommended protecting the uprights inside the aisles.

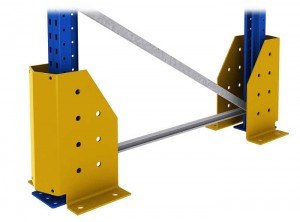

Racking protection adecuate for corners

Racking protection adecuate for corners

Racking protection for interior of aisles and corners

Racking protection for interior of aisles and corners

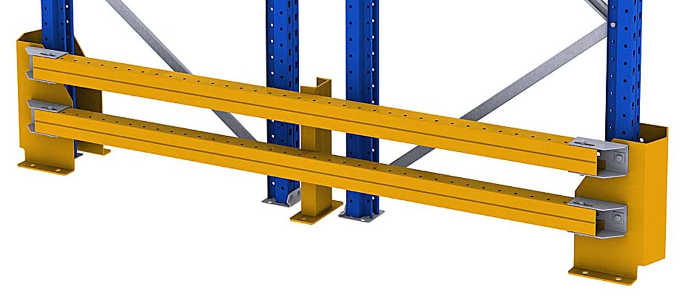

Integral protections. It is advisable placing integral protection at the ends of each run next to a driving lane, as well as in tunnel passages.

Integral protection

Cross beams

Cross beams rest on the racking beam in the depth without needing any additional fixing element, perfoming the following functions:

- Supporting the loading units with smaller dimensions than the loading level.

- To increase the stability of the loading unit depending on:

- Type of pallet used.

- Conservation / deterioration status of the pallets.

- Position of the pallet on the racking (normal or rotated pallet storage).

- Poor supporting surface of the pallets on the beams due to not recommended load excentricities (ie Europallet on 1.000 mm. deep frame).

- Inreasing the rigidity of the loading level with chipboard decking.

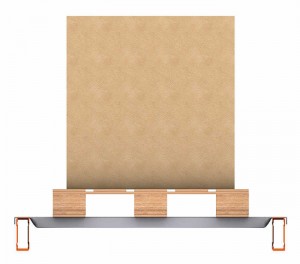

Cross beams for pallets

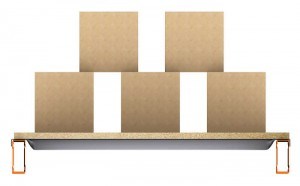

Cross beams with wooden decking

Safety mesh and fall protection

These elements are designed to protect security areas from falling goods. Installing them is recommendable.

- Security enclosures: close or delimita all type of security, insulation or restricted areas.

- Fall protection mesh: to protect security and work areas from possible fall off stored goods on racking.

Frame extensions

Frame extensions protect from side falls of goods on the aisle or on contiguous loading levels.

Although the norm specifies that the outer frames of racking runs have to be 0,5 meters higher than the last loading level (and 0,1 meters the intermediate frames), it is recommended extending the lateral frames to the height of the stored loading units to protect the personnel from accidentally falling goods from the racking.

When designing and using a racking installation, it is recommended and even necessary taking into account security measures and prevention of accidents to ensure operational safety reducing risks for both goods and individuals.