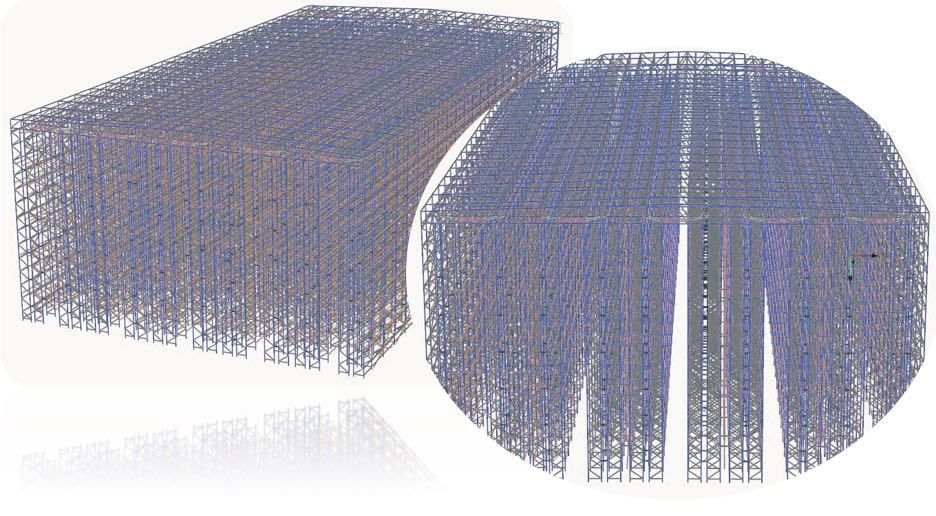

The structures that make up the industrial racking are assemblies made up of low-thickness profiles with specific geometries for this sector. The calculation of these structures entails a certain level of difficulty due to the complexity of the sections of the profiles used, in addition to other factors such as the joints between the various components. This makes a correct knowledge of its real behavior of great importance for the calculation and design.

With the information obtained, it has been possible to carry out more precise calculations and simulations, which allow optimizing the design, allowing this to project lighter and more efficient structures.

This calculation and design optimization is framed within the RIS3 scientific-technological priorities. Globally, the work is aligned with the objective “Recover industrial leadership through technology”, the basic skills of the industrial processes of production and transformation of steel are promoted as a pattern of specialization, consolidating an environment of open innovation .

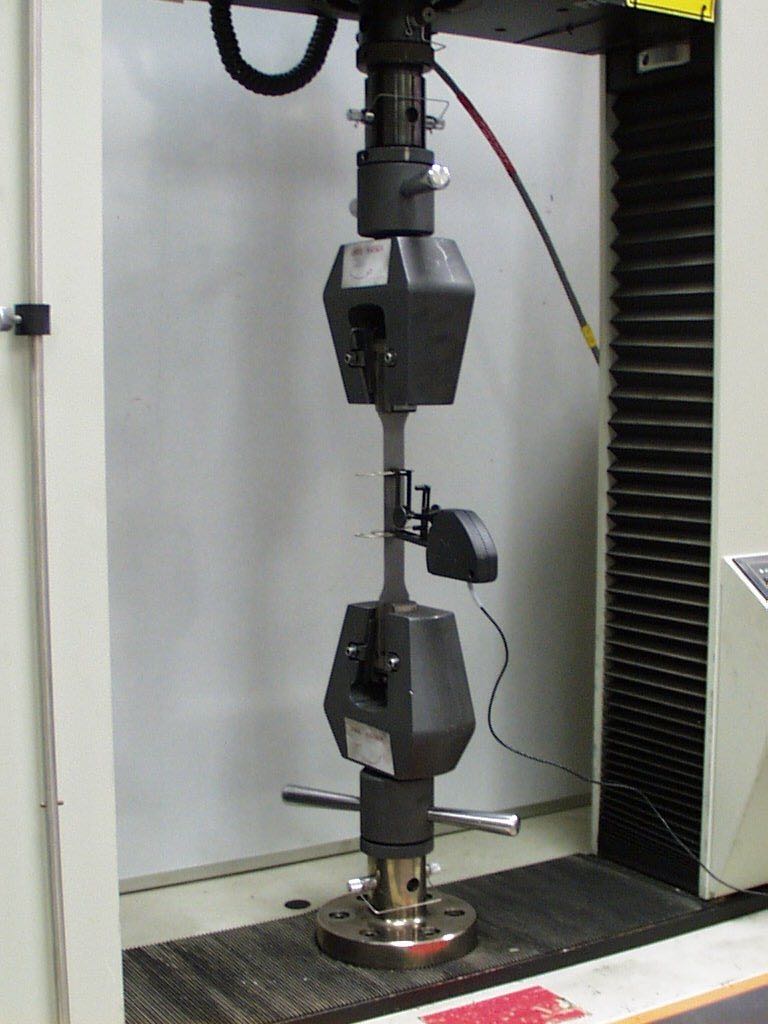

To carry out this first study, 2 tests framed within the Standard EN 15512: 2020 “Storage in metal shelves. Adjustable rack for palletized cargo. Principles for structural design”.

Uniaxial tensile test according to EN ISO 6892-1

It allows knowing the real mechanical properties of the material used in the manufacture of the various components of the rack structure.

Short strut compression test

It allows knowing the maximum load supported by the compression prop and determining the real effective area of the section, since the complex geometry of the profile makes it difficult to evaluate the behavior through theoretical calculations (failures due to localized buckling). This effective area will be used in the calculations and verifications of the rack designs.

Given the complexity of the geometry of this type of profiles and the infinity of holes necessary for the positioning of the load beams, it is necessary to determine their actual resistance values.

Carrying out this test allows knowing the maximum load supported by the strut in compression and determining the real effective area of the strut section. This effective area will be used in the calculations and simulations of the rack designs.

In this study, 13 different strut geometries were characterized.

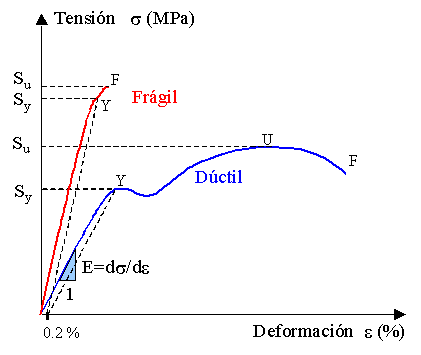

The tests were carried out following the EN 15520 standard, section A.2.1. The load was applied by 2 specific tools articulated at their ends (see Stress Deformation Graph).

Once the tests were carried out, and the maximum load values were obtained, the results were adjusted according to the criteria established by the EN 15520 standard. For this, the real values of both the elastic limit (obtained in the tests of traction), the geometry of the profile and its real thickness (by direct measurement of the tested props).

NOEGA Systems is a company specialized in the design, calculation, manufacture, supply and assembly of automatic installations of storage systems for all types of loads, and in intralogistics advice.

We have highly qualified personnel with extensive experience in the industrial storage sector, which allows us to provide the best response to the needs of each project, from manual picking systems to automated clad-rack installations.

In addition, we are the first entity accredited by ENAC, accreditation No. 281/EI466, for the Technical Inspection of Shelving and storage systems specified in UNE 58011.

If your company needs advice on these matters, do not hesitate to contact us.