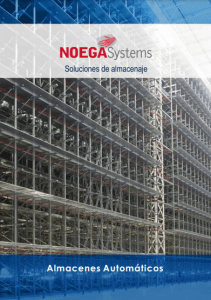

Automated Warehouses

Home » Prototipo almacen automatico

Description

What is an automated warehouse?

We can define an automated warehouse as a storage installation in which both machines and automated systems are responsible for carrying out all types of operations related to the stored goods.

These automated warehouses are made up of racks, which are responsible for storing the goods, and automated equipment, responsible for managing the storage of the automated warehouse.

The automated warehouses are designed to be operated automatically by means of stacker cranes for the storage of boxes (Miniload type), pallets and even textiles hung on hangers. This storage system is known as the hanging garment system.

Warehouse automation has become a key tool for improving efficiency in the supply chain and increasing value for companies.

With a highly competitive environment and ever-tightening deadlines, warehouse automation is seen as a way to increase productivity and provide a faster, more efficient service.

Are automated warehouses safe?

Automated warehouses are usually very secure due to the technology used to control and monitor inventory, as well as the automation of storage and distribution processes.

In addition, integrated security systems, such as security cameras and alarm systems, help to ensure inventory security and prevent theft.

What are the benefits of using an automated warehouse?

In what types of companies are automated warehouses used?

Automated warehouses are used in a variety of industries, including logistics, e-commerce, manufacturing, agriculture, distribution, retail and utilities.

These systems are particularly useful in companies with high inventory volumes and a wide variety of products.

Features

Characteristics of automated warehouses

- Automation: automated warehouses use technologies such as robots, automatic control systems and automatic reading devices to perform tasks autonomously and reduce the need for human intervention.

- Compact storage: automated warehouses use vertical and horizontal storage strategies to make the best use of available space.

- Precise stock control: these warehouses use automated inventory systems to accurately track incoming and outgoing goods.

- Automated warehouses use technologies such as robotics and artificial intelligence to pick orders quickly and accurately.

- These warehousing systems require less maintenance due to reduced damage and improved storage efficiency.

Advantages

Advantages of automated warehouses

- Automated warehouses allow for compact storage, reducing storage costs and improving space efficiency.

- Automation enables precise stock control, helping to avoid problems of over- or under-inventory and to maintain a constant flow of goods.

- Orders are picked quickly and accurately, resulting in more efficient delivery and improved customer satisfaction.

- Automation provides greater efficiency in the management of incoming and outgoing goods, which improves the efficiency and effectiveness of the logistics process.

- Automated warehouses allow significant savings in time, space and money by reducing the need for manpower and improving warehouse efficiency.

- The automation of warehouses enables an increase in the productivity of the logistics activity, as it reduces time and increases the efficiency of the process.

- Automated warehouses require less maintenance due to reduced damage and improved storage efficiency.

- Thanks to automation in warehouses, an increase in the safety of personnel and goods can be achieved, as it reduces the need for manual handling and improves the precision in the management of inputs and outputs.

Applications

Applications of automated warehouses to improve your warehouse

Automated warehouses are a good storage option for warehouses where the volume of incoming and outgoing goods is very high.

The ability to adapt to goods of all sizes makes this system suitable for any type of business.

Other Noega Systems products

NOEGA Systems automatic storage systems

NOEGA Systems puts the most advanced technology at the service of industrial storage. The automation of logistic and storage processes through the application of advanced robotised technologies requires storage systems and industrial racking adapted to the requirements of the project and the operational specifications.

Our objective is to innovate in order to improve, both in new products and in the optimisation of existing ones, and to this end we have a testing laboratory where we verify the behaviour of the different components of each storage system, carrying out load, resistance, buckling, etc. tests.

Downloads

Referencias